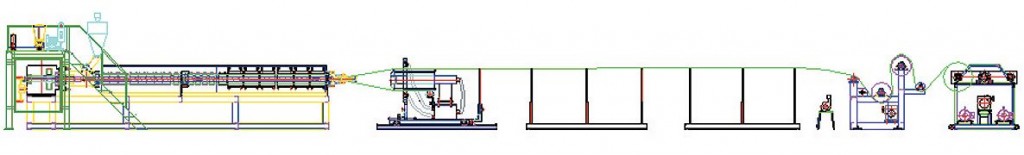

NPE Foam Sheet Extrusion Line, EPE Foam Sheet Extrusion Line

Non-Crosslinked PE Foam Sheet Extrusion Line, equipped with a single extruder, unique screw and economical extruding system, produces extruded expanded cellular polyethylene foam sheet of innumerable closed cell in continuous roll for cushioning, packaging, and insulation materials.

- Our single extruder, an integral component of the NPE Foam Sheet Extrusion Line enables an optimal foaming and maximum output.

- A unique screw provides an intensive mixing and enables the production of quality foam sheet with any cell size and density.

- Our dies, specially manufactured for its high tolerance, provide an efficient process and flexibility to create the highest quality foam to meet customer’s diverse demands.

- Auto temp. control via PID temp. control or PLC controlled touch screen on customers request.

- Hydraulic screen change system enables a continual production even during changing screens.

- AC motor and variable frequency inverter control system are durable at any harsh factory environment.

- Our Three-Way Special Cooling System inside of dies and inside of screw guarantees low density foam with noticeably short aging time enabling direct lamination with film. This system is applicable to both single extruder and tandem extruder.

Characteristics of NPE, EPE foam sheet extruder

- Superior cushioning

- Great heat-insulating power

- High buoyancy

- Little water absorption, outstanding weather-proof and chemical resistance

- Soft, strong and easy to fabricate

Specification

*Premium Model (L/D=62:1, with special cooling system)

| Model No. | PI-PE-SC105 | PI-PE-SC135 | PI-PE-SC150 | PI-PE-SC180 | PI-PE-SC200 |

| Max. capacity | 160kg/hr | 320kg/hr | 450kg/hr | 550kg/hr | 750kg/hr |

| Thickness range | 0.5~5mm | 0.5~8mm | 1~13mm | 2~15mm | 3~15mm |

| Min. density | 16kg/m3 | 16kg/m3 | 16kg/m3 | 16kg/m3 | 16kg/m3 |

| Max. density | 100kg/m3 | 100kg/m3 | 100kg/m3 | 100kg/m3 | 100kg/m3 |

| Electricity | 105kw | 150kw | 185kw | 270kw | 340kw |

*Standard Model (L/D=52:1, without special cooling system)

| Model No. | PI-PE-105 | PI-PE-135 | PI-PE-150 | PI-PE-180 | PI-PE-200 |

| Max. capacity | 160kg/hr | 320kg/hr | 450kg/hr | 550kg/hr | 750kg/hr |

| Thickness range | 0.5~5mm | 0.5~8mm | 1~13mm | 2~15mm | 3~15mm |

| Min. density | 18kg/m3 | 20kg/m3 | 22kg/m3 | 22kg/m3 | 22kg/m3 |

| Max. density | 35kg/m3 | 35kg/m3 | 35kg/m3 | 35kg/m3 | 35kg/m3 |

| Electricity | 105kw | 150kw | 185kw | 270kw | 340kw |

Application

- Cushioning and packaging materials for electrical equipment, pottery, glassware, etc

- Insulation materials for agriculture and building purpose

- Back-up materials for joint-fillers

- Anti-static foam protects static sensitive electronical components

- Insulation material for ice-cream and frozen foods

EPE foam sheet extrusion line FAQ

1. What is difference between EPE and XPE foam ?

EPE (non-crosslinked polyethylene) and XPE (chemically crosslinked polyethylene) have different manufacturing process, resulting in distinct properties. EPE has higher flexibility, cushioning, and lower cost whereas XPE foam has higher density, better thermal insulation, and water resistance.

2. What kind of gas is used in EPE foam extrusion?

Liquid type LPG (Butane mixed with propane at the ratio of 80:20 or 70:30) is generally used because good cooling system in our extruder and patent additive reduce aging time effectively.

In terms of aging, 100% propane is advantageous for sheet production because it diffuses fast and cheap but its handling is not easy.

3. What is advantage of Pacific EPE foam extruder?

Our EPE foam sheet extruder has three way special cooling system and long L/D to produce light, strong and resilient foam with significantly short aging time by using less gas.

Auto Cutting / Winding / Packing Unit with Paper Core for Thin Foam