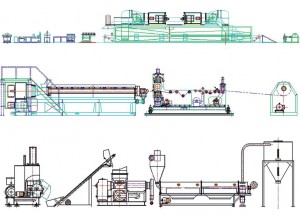

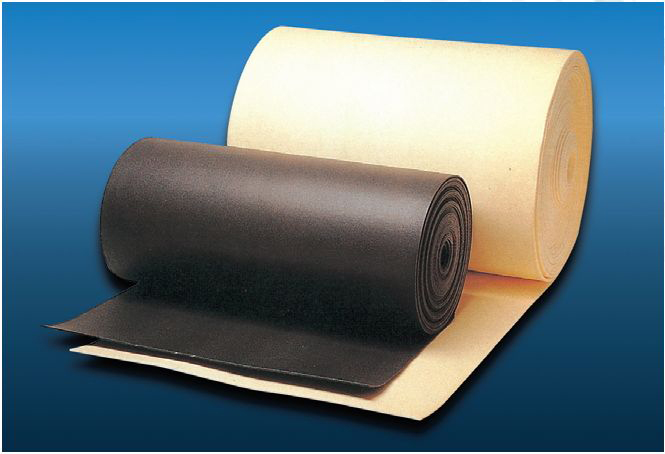

XLPE Foam Sheet Extrusion Line

Features of the machine

Characteristics of XLPE foam

- Superior cushioning

- Great heat-insulating power

- High buoyancy

- Little water absorption

- Outstanding weather stability and chemical resistance

- Soft, strong with beauty

- Easy to fabricate

- High thermal stability

Specification

| Model No. | PI-XPE-150 | PI-XPE-170 |

| Capactiy | Max. 150kg/hr | Max. 250kg/hr |

| Sheet width | Max. 1600mm | Max. 2400mm |

| Sheet thickness | Max. 15mm | Max. 15mm |

| Density | 25~200kg/m3 | 25-200kg/m3 |

| Electricity | 350kw | 500kw |

Applications

- Automobile, marine, and aerospace vehicles

- Building/construction thermal insulation, and moisture resistance

- All kinds of single or double coated tape product

- Camping mats and hockey helmets

- Healthcare appliance type products

XLPE Foam Sheet Extrusion Line FAQ

1. What is application of XLPE foam??

XLPE (crosslinked PE) foam is closed cell foam with superior cushioning, great heat insulating power, high thermal stability and easy to fabricate. So, it is widely used for construction, packaging, automotive, sports & leisure and medical & healthcare industry.

2. What is the manufacturing process of XLPE foam?

Kneading, pelletizing, blending, mother sheet extruding, crosslinking & foaming, cooling, winding, cutting and packing is the general whole process to produce XPE foam.

3. Which kinds of converting is available by XLPE foam?

Thermoforming, cutting/slitting, laminating, adhesive coating, die-cutting is available for wide applications.