XPS Foam Board Extrusion Line (XPS Line)

» XPS Foam Board Extrusion Line Features

XPS Foam Board Extrusion Line, manufactured by the most advanced technology, produces homogeneous, closed cell structured extruded polystyrene foam board.

∙ Our tandem extruder, an integral component of the XPS Foam Board Extrusion Line consists of

– A primary extruder which melts and intensively mixes XPS with a blowing gas and other additives.

– A secondary extruder optimizes a cooling and forwards the melt to the foaming die enabling proper and maximum output.

∙ A unique screw provides an intensive mixing and enables the production of quality foam sheet with any cell size, density, flexibility, and surface texture.

∙ Our dies, engineered to high tolerances to specified process requirements, provide efficient process and flexibility to create the highest quality foam to meet cutomer’s diverse demands.

∙ Auto temp. control via PID temp. control or PLC controlled touch screen on customer’s request.

∙ Auto cooling system on the secondary extruder with AL cast heaters is available.

∙ Hydraulic screen change system enables a continual production even during changing screens.

∙ AC motor and variable frequency inverter control system are durable at any harsh factory environment.

» XPS Foam Board Extrusion Line Production procedure

Tandem extruder for homogeneous melt ![]() T-die & calibration for forming a solidified board

T-die & calibration for forming a solidified board ![]() Edge-trimming & longitudinal-cutting for required dimension

Edge-trimming & longitudinal-cutting for required dimension ![]() Stacking and packing machine

Stacking and packing machine

» XPS Foam Board Extrusion Line Specifications

* CO₂ Type

| Model No. | PI-XPS T65-100 | PI-XPS T90-200 |

|---|---|---|

| Capacity | 550kg/hr | 800kg/hr |

| Sheet width | 600mm or 900mm | 600mm or 900mm |

| Thickness range | 20~100mm | 30~150mm |

| Min. density | 30kg/m³ | 30kg/m³ |

| Screw diameter | Primary: 65mm (Twin screw) Secondary: 100mm |

Primary: 90mm (Twin screw) Secondary: 200mm |

| Blowing agent | Mixture of CO₂ and Ethanol or DME | |

* Freon Type

| Model No. | PI-XPS 120-150 | PI-XPS 150-200 |

|---|---|---|

| Capacity | 400kg/h | 700kg/h |

| Sheet width | 600mm or 900mm | 600mm or 900mm |

| Thickness range | 20~100mm | 30~100mm |

| Min. density | 28kg/m³ | 28kg/m³ |

| Screw diameter | Primary: 120mm Secondary: 150mm |

Primary: 150mm Secondary: 200mm |

| Blowing agent | 100% Freon 132A or 134A, Mixture of Freon and DME or Butane | |

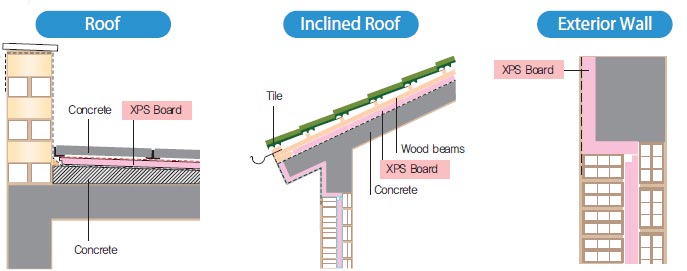

» XPS Foam Board Extrusion Line Applications

– Ceiling product : office, council rooms, lobbies, halls, department store, gyms, auditoriums, living rooms, schools, etc.

– Exterior wall product : outer/inner walls, floors, partitions, stairways for buildings etc.

– Floor product : apartment, living rooms, kitchen, bed rooms, house veranda, etc.